The Delta 3-Way Diverter Valve is a versatile plumbing component designed to manage water flow between multiple shower fixtures. It integrates seamlessly with Deltas shower systems, offering a reliable solution for directing water to shower heads, handheld sprayers, or body sprayers.

1.1 Overview of the Delta 3-Way Diverter Valve

The Delta 3-Way Diverter Valve is a high-quality plumbing component designed to efficiently manage water flow in shower systems. It allows users to direct water to multiple fixtures like showerheads, handheld sprayers, or body sprays. Built for durability and ease of use, this valve integrates seamlessly with Delta shower systems, ensuring reliable performance and a superior showering experience.

1.2 Importance of the Diverter Valve in Shower Systems

The Diverter Valve plays a crucial role in shower systems by enabling users to control water flow between multiple fixtures. It enhances the showering experience by allowing seamless switching between showerheads, handheld sprayers, and body sprays. This functionality not only improves convenience but also ensures efficient water distribution, making it an essential component for modern shower setups.

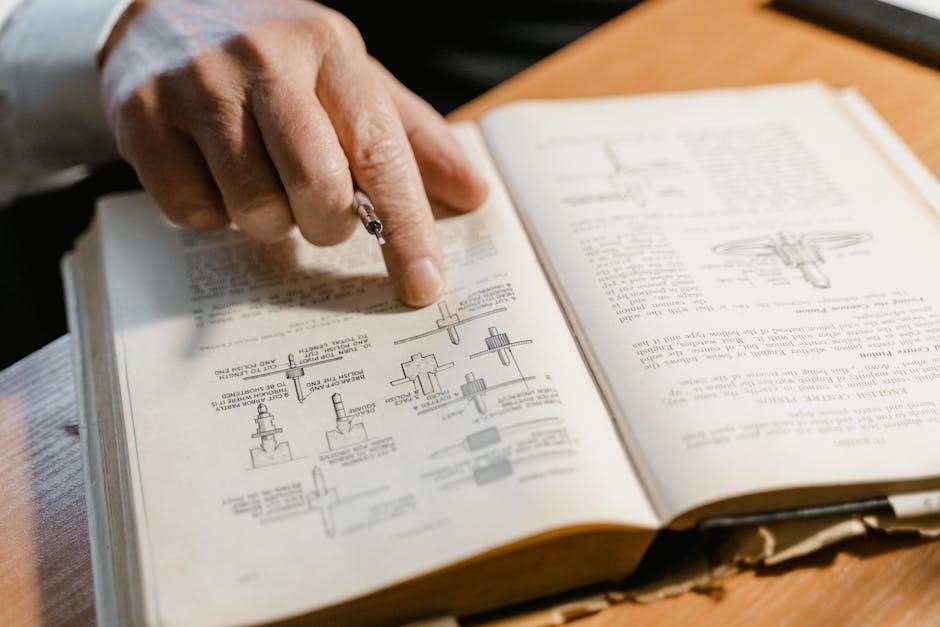

Key Components of the Delta 3-Way Diverter Valve

The Delta 3-Way Diverter Valve includes a diverter cartridge, diverter sleeve, and ports for water flow direction. These components ensure precise control and reliable performance in shower systems.

2.1 Diverter Cartridge

The diverter cartridge is the core component of the Delta 3-Way Diverter Valve, controlling water flow between shower fixtures. It features a locating pin for proper alignment during installation. A light coating of plumber’s grease on the O-rings aids assembly. The cartridge must align with the rough-in body to ensure smooth operation and prevent leaks, making it essential for precise water distribution in shower systems.

2.2 Diverter Sleeve

The diverter sleeve works in tandem with the cartridge to control water flow direction. It slides over the cartridge stem, ensuring proper alignment and smooth operation. A light coating of plumber’s grease on the sleeve’s O-rings can facilitate easier installation. The sleeve’s design ensures leak-free performance and precise water distribution, making it a critical component for optimal functionality in shower systems. Proper installation ensures durability and reliable operation.

2.3 Ports and Water Flow Directions

The Delta 3-Way Diverter Valve features three ports: one inlet for incoming water and two outlets for directing flow to different fixtures. The valve allows water to flow to one or multiple shower components, such as showerheads or body sprayers. The flow direction is controlled by the diverter handle, which redirects water based on the selected setting. Proper installation ensures smooth water distribution and prevents leaks, optimizing shower system performance.

Choosing the Right Diverter Valve for Your Needs

Choosing the right diverter valve involves assessing your shower system’s needs, considering fixture count, and ensuring Delta compatibility. Opt for a 3-setting valve for simplicity or a 6-setting for advanced control, noting flow rate and pressure considerations.

3.1 Understanding 3-Setting vs. 6-Setting Diverter Valves

The Delta 3-setting diverter valve is ideal for basic shower systems with two or three fixtures, offering straightforward water distribution. The 6-setting diverter valve provides enhanced control, suitable for complex systems with multiple fixtures like rain showers and body sprays. Choose based on your shower’s complexity and desired water flow customization, ensuring compatibility with your shower system’s requirements for optimal performance and satisfaction.

3.2 Compatibility with Delta Shower Systems

The Delta 3-Way Diverter Valve is specifically designed to work seamlessly with Delta shower systems, ensuring optimal performance and compatibility. It pairs perfectly with Delta’s MultiChoice Universal Valve and other shower fixtures, offering a reliable and integrated solution for directing water flow. The valve is backed by Delta’s Lifetime Limited Warranty, providing peace of mind for its durability and performance in your shower setup.

3.3 Considerations for Water Flow Rate and Pressure

When selecting the Delta 3-Way Diverter Valve, consider the water flow rate and pressure requirements of your shower system. The valve’s performance depends on the components being used, such as shower heads or body sprayers, and the trim or cartridge of the control valve. Proper installation ensures optimal water distribution and pressure maintenance. Always use genuine Delta parts for compatibility and to uphold the product’s warranty.

Pre-Installation Preparation

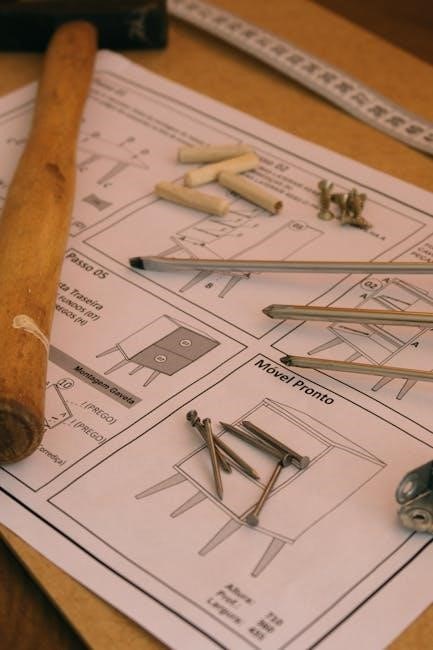

Pre-installation involves gathering tools like pliers and plumber’s tape, and materials like grease for O-rings. Ensure water supply is shut off and the area is clear.

4.1 Tools and Materials Needed

Essential tools include adjustable wrench, pliers, screwdriver, and plumber’s tape. Materials needed are grease for O-rings, Teflon tape, and a bucket to catch water during installation. Gather all items beforehand to ensure a smooth process without delays.

4.2 Shutting Off the Water Supply

Locate the water shut-off valves, typically near the water heater or under the sink. Turn both hot and cold valves clockwise using an adjustable wrench until they stop. Open the shower drain or lowest faucet to drain the system. Verify water is off by turning the shower handle to ensure no water flows. This step prevents water spillage during installation.

4.3 Removing Existing Fixtures (If Applicable)

Disconnect plumbing lines from the existing valve using an adjustable wrench. Gently pull the valve out of the wall or shower system; Remove any old cartridges or sleeves by twisting and lifting. Ensure no debris remains in the plumbing lines. Clean the area thoroughly before preparing for the new diverter valve installation. This step ensures a smooth and clutter-free installation process for the Delta 3-Way Diverter Valve.

Installation Process

- Mount the diverter valve rough-in securely to the shower wall.

- Connect plumbing lines, ensuring proper alignment and sealing.

- Install the diverter cartridge and sleeve carefully.

- Perform final checks for leaks and functionality.

5.1 Mounting the Diverter Valve Rough-In

Begin by preparing the shower wall and ensuring the area is clean and dry. Apply a light coating of plumber’s grease to the O-rings on the diverter cartridge. Carefully align the cartridge with the rough-in body, ensuring the locating pin matches the mating hole. Gently slide the diverter sleeve over the cartridge stem and secure the rough-in to the wall using appropriate screws. Ensure the diverter is properly seated and aligned for smooth operation.

5.2 Connecting Plumbing Lines

Connect the plumbing lines to the diverter valve ports, ensuring each line is securely attached; Apply Teflon tape or plumber’s grease to the threads for a leak-proof seal. Align the water supply lines with the appropriate ports, ensuring proper flow direction. Tighten all connections firmly but avoid over-tightening, which could damage the valve. Double-check all connections for leaks before proceeding with the installation.

5.3 Installing the Diverter Cartridge

Gently insert the diverter cartridge into the rough-in valve, ensuring the locating pin on the cartridge aligns with the mating hole in the body. Apply a light coating of plumber’s grease to the O-rings for smooth installation. Slide the diverter sleeve over the cartridge stem, securing it firmly. Ensure all components are properly seated and aligned to guarantee optimal water flow control and prevent leaks during operation.

5.4 Final Checks and Testing

Turn the water supply back on and inspect all connections for leaks. Test each port to ensure proper water flow distribution. Cycle through all settings to confirm smooth operation of the diverter handle. Check for any unusual noises or resistance. Once satisfied, proceed with the final trim installation. Perform a final test to ensure all components function seamlessly together before completing the project.

Diverter Valve Setup and Configuration

Adjust the diverter handle to ensure smooth transitions between settings. Align all components properly to maintain consistent water flow. Test each port to confirm functionality and optimal performance.

6.1 Adjusting the Diverter Handle

Ensure the diverter handle is correctly positioned by aligning the “UP” marker on the sleeve with the handle. Gently rotate the handle to test each setting. Proper alignment ensures smooth water flow transitions between shower heads, handheld sprayers, or body sprays. Apply a light coating of plumber’s grease to o-rings for easier adjustment and to prevent leaks during operation.

6.2 Testing Water Flow Distribution

After installation, turn on the water supply slowly and test each port to ensure proper flow distribution. Check for leaks and confirm that water directs smoothly to the intended fixtures. Adjust the handle to verify even flow across all settings. Ensure the diverter aligns correctly with each port to prevent water diversion issues. Proper testing ensures optimal performance and a seamless shower experience.

6.3 Ensuring Proper Alignment of Components

Ensure the diverter cartridge is aligned correctly with the locating pin matching the rough-in body. Apply a light coating of plumber’s grease to O-rings for smooth installation. Verify the diverter sleeve is properly seated over the cartridge stem. Avoid forcing components into place, as this may cause misalignment. Double-check that all parts are securely fitted and operate smoothly, ensuring proper water flow distribution and handle functionality.

Troubleshooting Common Issues

Common issues include leaks, improper water flow distribution, and misaligned cartridges. Inspect O-rings for wear, ensure proper alignment during installation, and test connections for tightness to resolve problems effectively.

7.1 Leaks and Water Seepage

7.2 Improper Water Flow Distribution

Improper water flow distribution in the Delta 3-way diverter valve can occur due to misaligned cartridges or debris buildup. Check the cartridge alignment and ensure it matches the mating hole in the rough-in body. Clean or replace the cartridge if contaminated. Verify that all ports are unobstructed and properly connected. Adjust the handle to ensure smooth transition between settings and test water flow distribution after adjustments.

7.3 Cartridge Alignment Problems

Cartridge alignment issues can disrupt proper water flow. Ensure the locating pin on the cartridge aligns with the mating hole in the rough-in body. Misalignment may cause uneven water distribution or leakage. Gently adjust the cartridge position, ensuring it clicks securely into place. Apply a light coating of plumber’s grease to o-rings for smooth installation and proper sealing. Test the alignment by cycling through all settings to confirm functionality.

Maintenance and Care

Regularly clean the diverter valve with water and mild soap, then dry with a soft cloth. Avoid harsh chemicals to prevent damage. Maintain proper alignment and lubricate o-rings annually for smooth operation.

8.1 Cleaning the Diverter Valve

Regular cleaning ensures optimal performance. Use mild soap and water to wipe down surfaces, then dry with a soft cloth. Avoid harsh chemicals or abrasive cleaners, as they may damage finishes or seals. For internal components, apply a light coating of plumber’s grease to O-rings to maintain smooth operation. Periodically inspect and clean ports to prevent mineral buildup or debris accumulation, ensuring uninterrupted water flow and system efficiency.

8.2 Inspecting for Wear and Tear

Regularly inspect the diverter valve for signs of wear, such as leaks or mineral buildup. Check O-rings and gaskets for cracks or degradation. Ensure the cartridge is properly aligned and moving smoothly. Inspect ports for blockages or corrosion. Address any issues promptly to maintain optimal performance and prevent water flow disruptions. Replace worn-out parts with genuine Delta components to ensure longevity and warranty compliance.

8.3 Replacing Worn-Out Parts

Replace worn-out parts with genuine Delta components to maintain performance. Identify damaged elements like O-rings or cartridges and install new ones. Apply a light coating of plumber’s grease to ensure a watertight seal. Align the cartridge properly with the locating pin in the rough-in body. After installation, test the valve to ensure smooth operation and leak-free functionality. Always follow Delta’s replacement guidelines for optimal results.

Proper installation and maintenance of the Delta 3-Way Diverter Valve ensure optimal performance and longevity. Follow guidelines for a seamless experience and enhanced shower functionality.

9.1 Summary of Key Steps

Installing the Delta 3-Way Diverter Valve involves mounting the rough-in, connecting plumbing lines, and installing the cartridge. Ensure proper alignment and test water flow; Regular maintenance, like cleaning and inspecting parts, prevents leaks and wear. Refer to Delta’s manual for detailed steps and troubleshooting common issues for optimal functionality and longevity of your shower system.

9;2 Final Tips for a Seamless Experience

For a smooth installation and operation, ensure all connections are secure and properly aligned. Use genuine Delta parts to maintain performance and warranty. Apply plumber’s grease to o-rings for easier assembly. Regularly inspect and clean the valve to prevent mineral buildup. Follow Delta’s guidelines for water pressure and flow rate settings to optimize functionality and longevity of your shower system.

Additional Resources

10.1 Delta Faucet Official Installation Manuals

10.2 Video Guides and Tutorials

Delta Faucet offers video guides and tutorials on their official website and YouTube channel. These resources provide step-by-step installation instructions for the 3-Way Diverter Valve, including the R11000 model. Videos cover topics like initial setup, cartridge replacement, and troubleshooting. For example, the R11000 installation video includes a supply list and shortcuts for easy navigation, ensuring a smooth installation process for DIY enthusiasts and professionals alike.

10.3 Customer Support and Warranty Information

Delta Faucet provides exceptional customer support and a Lifetime Limited Warranty for their 3-Way Diverter Valve. For assistance, contact their customer service at 1-800-288-3970 or via email at customer.service@deltafaucet.com. The warranty ensures free replacements for defective parts during the coverage period. Visit their official website for detailed warranty terms and additional support resources.